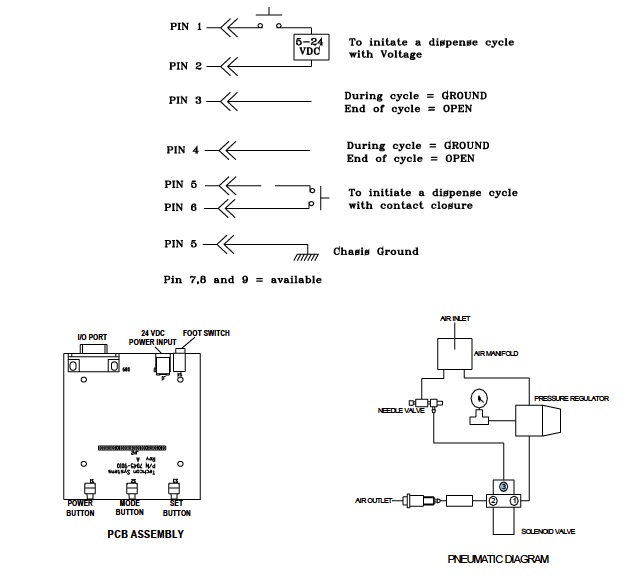

I/O connection guide for TS250, TS255, TS350 and TS355 dispensers/ controllers.

I/O Configuration and End of Cycle Switch

Upon completion of a dispense cycle, an open collector circuit closes and remains closed until the next dispense cycle. This circuit can be used to signal back to a host computer, start another device in sequence, or drive any other operations that need to be tied to the completion of the dispense cycle. Upon closure, (end of dispense cycle), power from an external source is allowed to pass through the circuit to operate a 5 to 24 VDC load. Power consumption must not exceed 250 mA. The load could be a relay, solenoid, counter, LED, or any device that will operate within a 5 to 24 VDC range and a maximum of 250 mA.

| Related Articles |

> How to attach the adapter assembly hose to the syringe barrel

> Watery liquid drips from either TS250, TS255, TS350, TS355 syringe dispensers

> Thick paste, gels, silicones, sealants, epoxies, etc not flowing or restricted when dispensing

> Time pressure dispensing tutorial

> Filling techniques for syringe barrels

> Advice for dispensing different fluid types

> Advice for dispensing sealants, grease and solder pastes

> Smooth flow tapered tips

> Bench-top fluid dispensing: Easy when you know how

> Dispensing System: Reducing maintenance requirements in dispensing applications

> Piston Comparison for 700 Series Dispensing Syringes

> Rotary Auger Valves � Pros and Cons

> Dispensing Adhesives Material Can Be Challenging

> Improving the Grease Dispensing Process

> Benchtop epoxy dispensing small shot

> The Negative Effects of Reusing Syringes and Accessories

> Fluid Viscosity Chart Table

> Dispense valve material selection guide

> TS5600 series diaphragm valves specifications

> TS5420 needle valve specifications

> TS5520 spray valve specifications

> TS1212 pinch tube valve specifications

> TS1201 pinch tube pen valve specifications

> Fluid dot anatomy volume compared to deposit diameter

> General advice for handling Cyanoacrylates in bottles

> Avoid needle tips clogging using Cyanoacrylate adhesives

> Basic TS250/ TS255 bench dispensers manual applications

> Reason to use a brush tip with a timed pulse dispenser

> If you use Cyanoacrylates...

> Some typical dispensing applications

> Reducing Hand Fatigue and Variability in Medical Device Assembly Processes

> General advice for handling Cyanoacrylates adhesives

> Viscosity of Fluids to Compare With

> Dispenser spares & accessories

> Spray Valve Coverage Chart

> Techcon cartridge gun spares & accessories

> Techcon spool valve spares & accessories

> Techcon spray valve spares & accessories

> Techcon needle valve spares & accessories

> Fisnar peristaltic pump spares & accessories

> Dispensing tip gauge size chart

> Benchtop dispensing robots

> Dilatent Definition

> Conformal Coating Product Description - a brief guide

> Potting Encapsulating Product Description - a brief guide

> Sealants Product Description - a brief guide

> Adhesive Technical Information Chart

> Adhesive Dispensing Valve Selection Guide

> Chemistry Technical Information

> Volume, Weight and Length Conversions

> Temperature Conversions

> Durometer Conversions

> Fluid Coverage Information

> Adhesive Dispensing Luer Lock & Luer Slip Tip Attachment

> Accelerator Definition

> Activator Definition

> Acrylic Definition

> Alloy Definition

> Anaerobic Definition

> Aqueous Definition

> Balling Definition

> Braze Paste Definition

> Caulk Definition

> Centipoise Definition

> Conductive Epoxy Definition

> Cyanoacrylate Definition

> Epoxy Definition

> Hot Melt Definition

> Polyurethane Definition

> Silicone Definition

|

|