|

|

|

TS250 dispenser training guide and setting up Last Updated: 01/01/2012 |

|

A New Dimension to Bench-top Fluid Dispensing

PRODUCTIVITY-ENHANCING DIGITAL

TS250 Series

Safety Precautions

� Do not operate this unit in excess of maximum ratings/settings � Always wear appropriate personal protective clothing or apparel � Use only approved power adaptor models:

? PSA15R-240P(ZJ) ? PW118RA2403B01 ? PW118RA2403H01 ? PW118RA2403M01

Symbol Definition

Pressure: Regulate air pressure Pressure: Regulate air pressure

Specifications

� Input Voltage: 24 VDC � Maximum Air Output Pressure: � TS250 = 100 psi (6.9 bars) � TS255 = 15 psi (1.0 bars) � Vacuum Force: 16� (406mm) of Hg � Timer: 0.020-60 seconds � Repeat Tolerance: +/- 0.001% � Cycle Mode: Continue, Purge (Manual), Interrupt � Cycle Rate: 600 cycles/minute

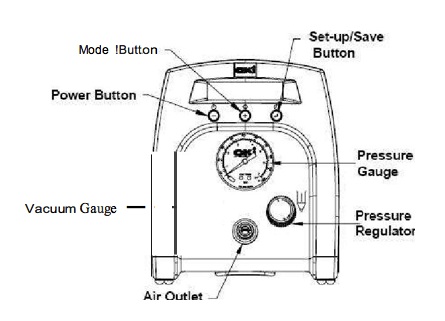

Features- Front View

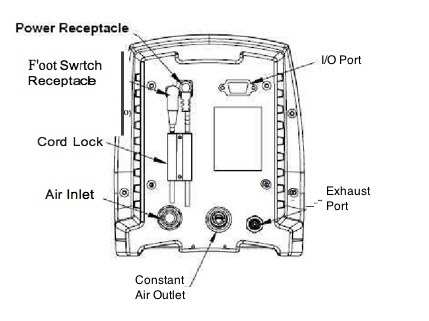

Features- Rear View

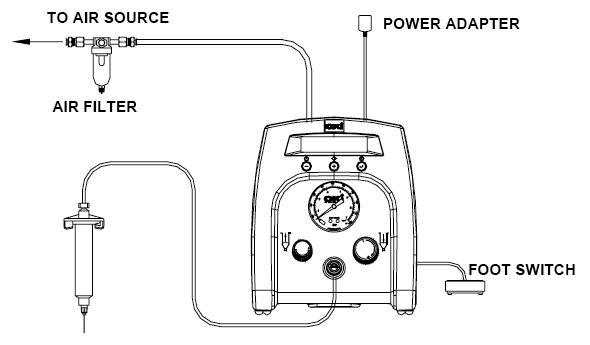

Typical Connection

Operation Modes and Display Indicators

� Mode = A process that performs a specific action or a group of actions that results in an expected outcome

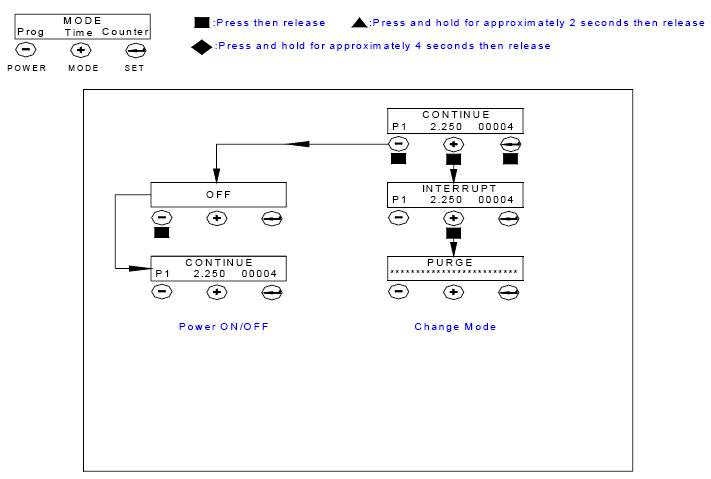

Setup- Operation Diagram (Mode Selection)

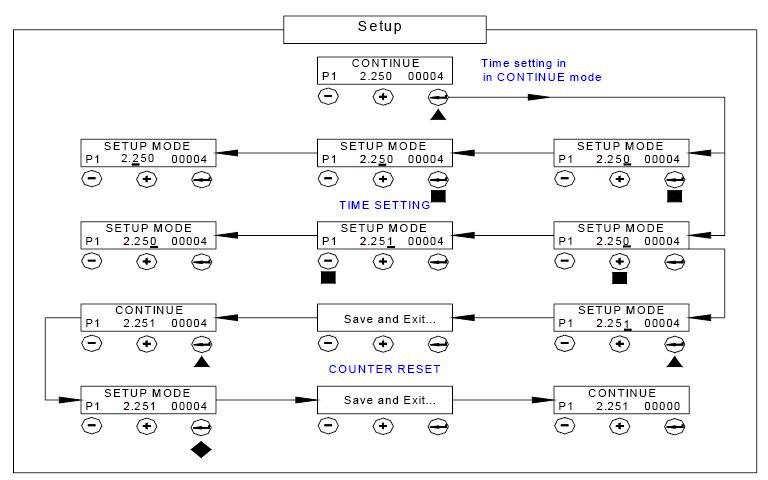

Setup- Operation Diagram (Time & Counter Setting)

Setup � Purge Dispense Cycle

1. Press Power Button to turn on unit

2. Press Mode Button to select

�Purge/ manual� Mode

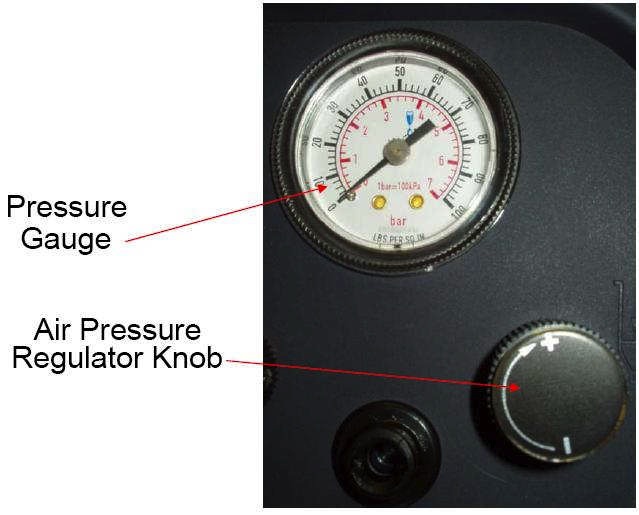

3. Rotate Air Pressure Regulator

knob clockwise (CW) until desired

pressure is

indicated on the pressure gauge

4. Attach Receiver

Head Assembly to syringe.

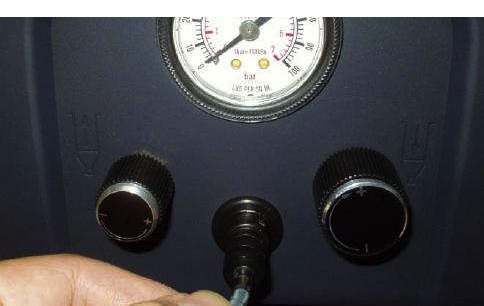

5. Connect plug end of

Receiver

Head Assembly to air

outlet

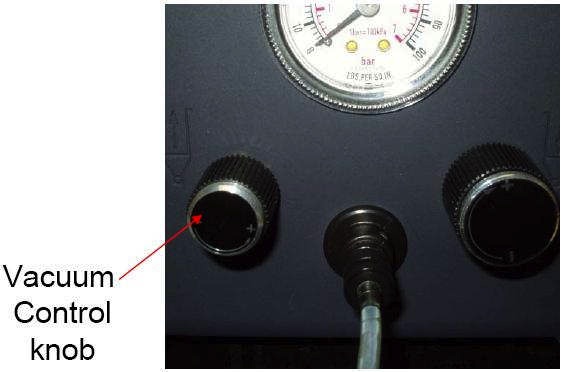

6. If vacuum �suck back� is needed, rotate Vacuum Control Knob

7. Depress Foot Switch to activate dispense cycle

Setup � Auto Dispense Cycle: Time Setting

1. Push Mode Button to select �CONTINUE� or

�INTERRUPT�

Mode

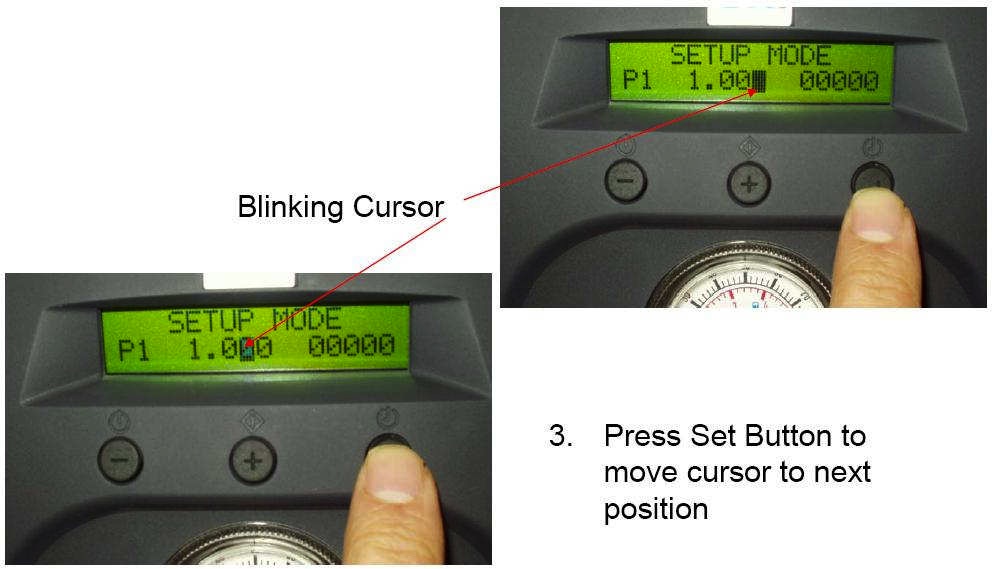

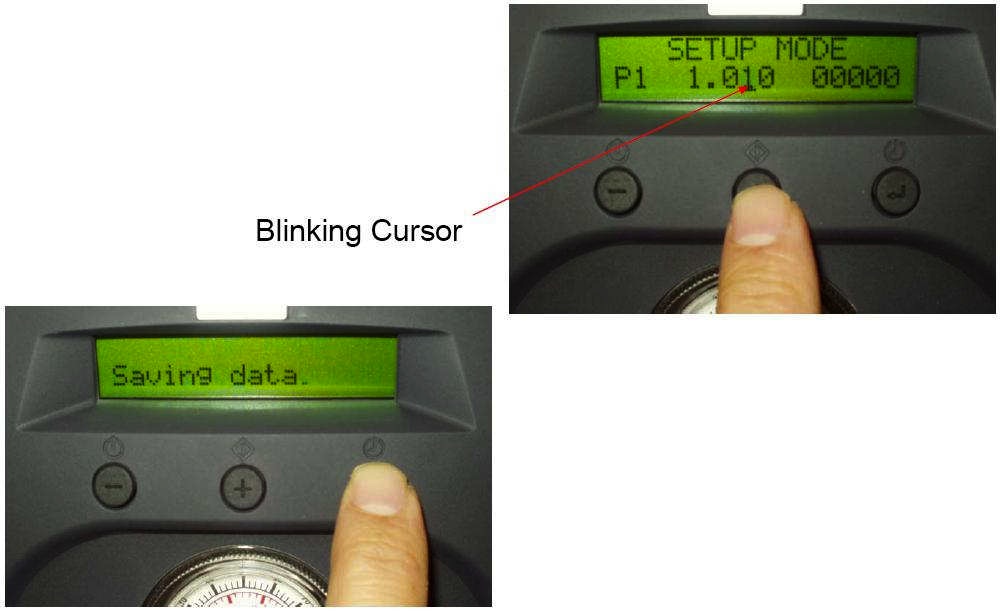

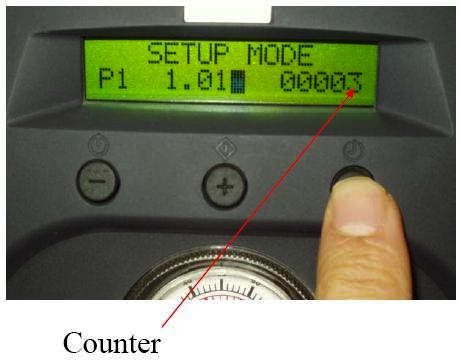

2. Press and hold Set Button for 2 seconds to enter �Setup� Mode (the last digit is highlighted with a blinking cursor)

4. Press (+) or (-) Activation Button to set desired dispense time

5. Press and hold Set Button for 2 seconds to save data

6. Depress Foot Switch to activate dispense cycle

Cycle Counter Reset

To reset counter: Press and hold Set Button for 2 seconds to enter Setup Mode then press and hold Set Button for 4 seconds to reset

Up to 65,535 cycles can be recorded

Troubleshooting

LCD does not light - No power input: check power connection: turn on power

Unit will not actuate - Foot Switch not plug in or loose: check Foot Switch connection - Defective Foot : replace Foot Switch - Loose connection inside unit: check for broken wires or loose connec- tions - Defective solenoid: replace solenoid - Defective PC board: replace PC board

Unit will not pressurise - Insufficient air pressure: increase air pressure - Air hose not plugged in: check air connection - Defective air regulator: replace air regulator

System will not pull vacuum - Vacuum setting is too low: increase vacuum setting - Defective venturi: replace venturi - Defective needle valve: replace needle valve

Inconsistent dispensing - Air bubbles in adhesive: remove air bubbles, decrease vacuum setting - Dispense time is too low: increase dispense time - Dispense needle tip starting to clog: replace dispensing tip

Maintenance

- Make sure air supply is clean and dry - recommend using an air filter such as part # TSD800-6

- Avoid connecting air supply in excess of 100 psi (6.9 bar) for TS250 and 15 psi (1.0 bar) for TS255

- Avoid turning barrels upside down or laying barrel so that mate- rial may run through airline to internal components - use inline filter for adapter # 881-000-000

- Use amyl alcohol to clean surface of unit housing

- Use soft cloth to clean LCD display

I/O Configuration - End of Cycle Switch

Pin Function

-

Pin 1 = voltage initiate + (5-24VDC)

Contact Information

TS250 and TS255 covered by 1 Year manufacturers warranty

Adhesive Dispensing Ltd

Tel. 0845 652 0058 |

V

V